Protecting People, Protecting Productivity

What is ISO/TS 19837:2018 – Safety of Machinery – Trapped Key Interlocking Devices?

ISO/TS 19837:2018 – Safety of Machinery – Trapped Key Interlocking Devices – Principles for design, selection and configuration is the first international ISO document devoted specifically to trapped key interlocking and answers many of the questions that have arisen relating to performance levels, key coding, and power interlocking. It is a significant step forward which will provide more choice for users of interlock devices and systems.

Trapped Key Interlocking has its roots in the rail and power distribution industries where sequential control was, and still is, critical to safe, continuous operation. In the 1960’s trapped key interlocking was gradually utilised by the manufacturing sector, where isolating machinery before gaining access, was the requirement.

Machinery with multiple energy sources and access points can be easily safeguarded using trapped key interlocks. Fortress Interlocks has developed specialised products over the years which can isolate air and hydraulic supplies as well as electrical power in sequence before allowing access points to be opened.

When ISO14119:2013 Safety of Machinery – Interlocking device associated with guards, Principles for design and selection, was published trapped key interlocking had become no more than an annex, even the scope was clear that it did not provide all the specific requirements for trapped

key systems. In many respects ISO14119:2013 served to confuse users and potential users familiar with decades of trapped key interlocks installations.

ISO/TS 19837:2018, three years in the making, is a welcome addition to the existing suite of machinery safety standards. Perhaps the most critical question addressed is where mechanical or hybrid mechanical/electrical systems sit in relation to performance levels introduced in ISO 13849.

Power Interlocking is now more properly referred to as “Isolation control through direct mechanical action” and falls within the Safety Related Part of The Control System. This coupled with the section “Validating performance level” makes evaluating performance levels for trapped key systems much clearer.

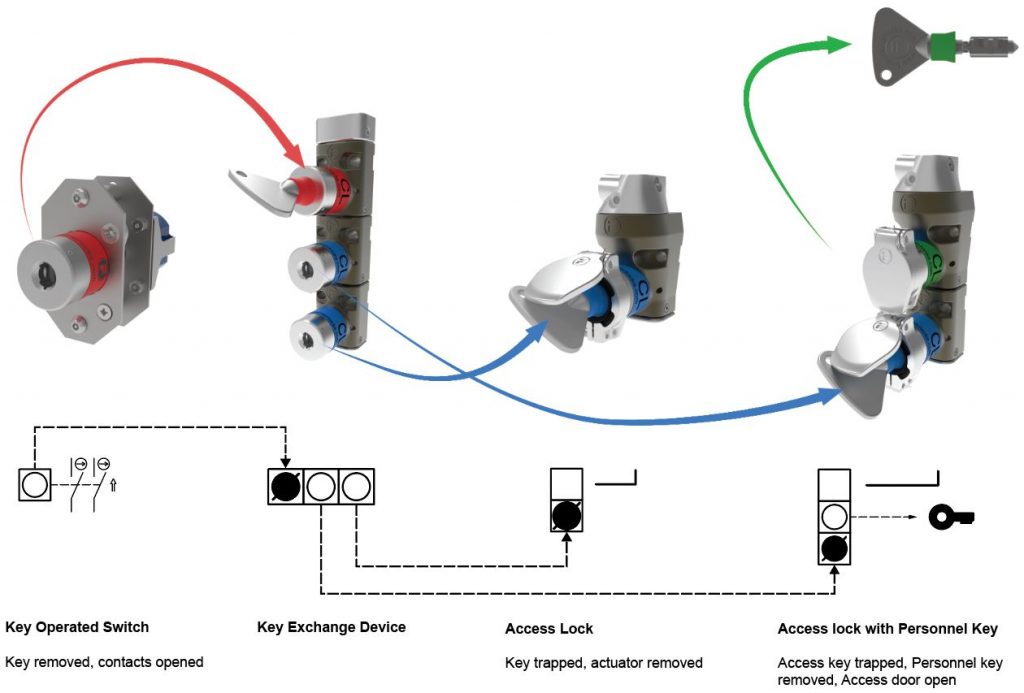

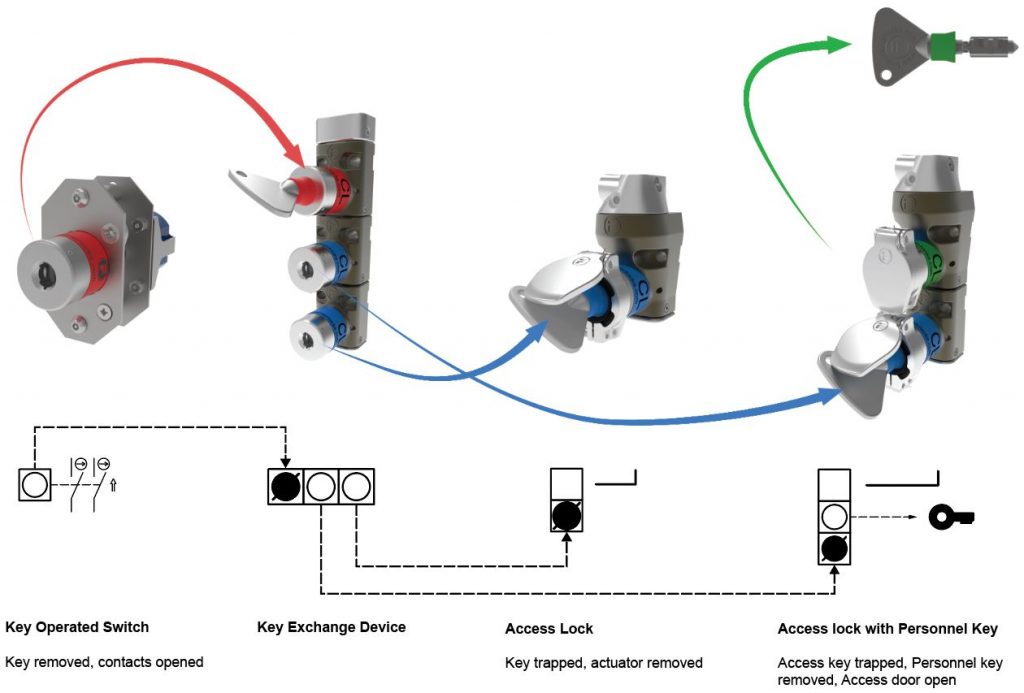

The difference between actuators and keys is cleared up, following the confusion created in ISO14119:2013, and both are addressed in the “Terms and definitions” and “Symbols and abbreviated terms” sections.

The need for a schematic detailing the trapped key system operation and establishing key coding appears under “Key Transfer Plan” and will provide users with an excellent tool in the system design phase as well as a documented system layout after installation. Key coding and management is also addressed extensively.

A much-needed standardisation of symbols to represent trapped key interlocks will make it easier for customers to understand schematics, and the excellent pictorial examples throughout the document are useful for those building a trapped key interlock system.

Jo Smith, Fortress Managing Director: “The publication of ISO/TS 19837 will help to keep trapped key interlocking at the forefront of machine safety in the future, it is very much welcomed by Fortress. We have worked hard to ensure Fortress products meet the most stringent safety standards and our trapped key interlocks are no exception. It is good to finally have a document that helps our customers understand better how trapped key interlocks fit within the international machinery safety standards.

For those seeking help our experienced team of sales engineers is able to provide support and guidance.”

About Fortress Interlocks

Fortress Interlocks designs and manufactures safety equipment, protecting lives in hazardous workplaces. Our interlocks work in sequence to ensure employees are safeguarded from dangerous machinery by eliminating the possibility of human error.

Over the last 40 years, Fortress has become well known in industry for innovative design, robust engineering and reliability. Headquarters are in Wolverhampton, UK, supporting offices and manufacturing facilities are in the USA, Netherlands, Australia and China, further supported by a global network of trusted distributors and channel partners.

Fortress’ current product portfolio includes:

- mGard – The only range of mechanical interlocks independently certified to PLe applications

- amGardpro – Heavy duty safety gate switches with connectivity and trapped key integration

- amGardS40 – Stainless steel IP69K safety gate switches

- tGard – Medium duty interlocks with configurable built-in control functionality

- ncGard – A complete range of non-contact safety switches

Contact Information

Hannah Chopra

Marketing & Communications Manager