READ COMPLEX AND CHALLENGING CODES UNDER ANY CONDITION WITH DEEP LEARNING-BASED OCR

Consistent, easily readable fonts set against a light or dark background can be solved well enough with traditional machine vision. But manufacturers need a new kind of dedicated OCR solution for when confusing backgrounds and imaging issues challenge their machine vision systems, and when the number and type of application-specific fonts are unpredictable. Badly deformed, skewed, and poorly etched codes are some of the common culprits. Other tricky codes are those involving low-contrast characters or codes printed, etched, dot-peened, or embossed on confusing backgrounds.

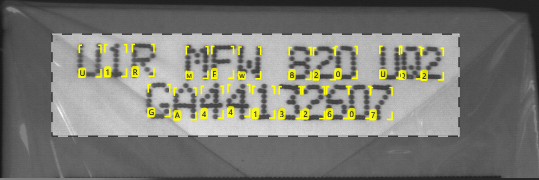

Imagine the time savings of a pre-trained optical character recognition (OCR) and verification (OCV) tool. By eliminating arduous training upfront, this tool would work out-of-the-box. And if an unrecognizable font did appear, likely because of specular glare, poor etching, or another cause of deformity, that tool could be retrained on the factory floor, and only on the problematic misread characters. That’s the promise of deep learning-based OCR and OCV tools, which rely on a pre-trained, omnifont library and only require training on application-specific fonts.

Let’s explore how deep learning-based software offers a radically easy, accurate alternative to these complex OCR/OCV inspection applications in different industries.

Manufacturers in the food and beverage or pharmaceutical industry must have reliable systems in place to recognize and verify the trail of information which follows each packaged good through the supply chain. In their efforts to ensure full package traceability, food and beverage and consumer products manufacturers sometimes confront challenging codes.

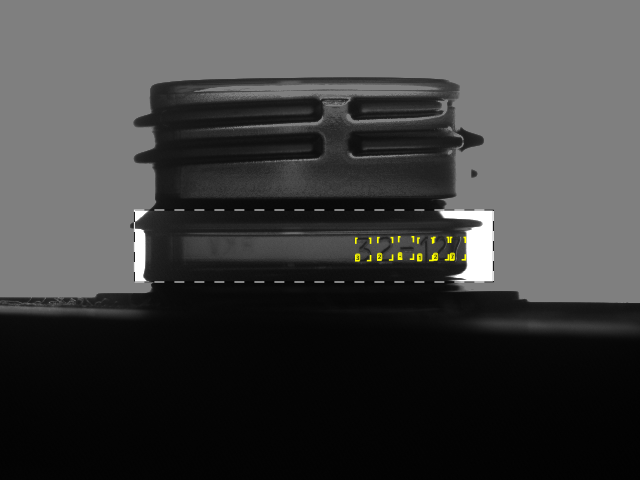

The usual suspects are either low-contrast characters printed on label-based packaging codes or deformed, embossed characters on injection-molded parts, such as a bottle cap. The codes may be used to match multi-part packaging or, more likely, contain date/lot codes that embed information about contents, origin, and date of manufacture. In these cases, manufacturers rely on OCR/OCV equipment to quickly locate affected products and pull them out of production or off shelves. Traditional OCR/OCV technology requires upfront training to learn various fonts and even then can struggle to decode poorly contrasted characters. Deep learning-based OCR/OCV technology doesn’t have the same limitations and is able to read most poorly contrasted letters and numbers automatically. By embracing deep learning-based technology, manufacturers can keep abreast of food safety and traceability laws and facilitate recalls with minimal impact on their production.

Automotive manufacturers as well as parts suppliers use serial numbers to track high-value parts through the supply chain and ensure they are matched with the correct assemblies. Many parts contain ten-digit, dot-peened serial numbers so that when errors occur during testing, the source can be traced. When dot-peened serial numbers become grossly deformed and illegible, this slows down the OCR and OCV processes and threatens effective traceability.

Deep learning-based OCR tools are effective and easy to deploy on codes printed onto challenging substrates and prone to deformity like dot-peened codes on metal parts, embossed characters on injection-molded products, label-based codes on packaging, and laser-etched codes on electronic components. Cognex Deep Learning’s OCR/OCV technology recognizes most alphanumeric text out-of-the-box and only requires brief upfront training to set the region of interest and character size. The system can retrain on misread characters quickly on the factory floor, so that manufacturers don’t miss a beat.

Find out more about Cognex’s Deep Learning-based OCR tool In-Sight ViDi Read by downloading the datasheet: https://connect.cognex.com/is-vidi-read-tool-LP_EN

Contact:

Cognex Germany Inc.

Emmy-Noether-Str. 11

76131 Karlsruhe

Cognex Sales: +44 121 296 5163

Email: contact.eu@cognex.com