Cost-saving eco parts cleaning solutions – Parts cleaning at the lowest cost to the planet, your technicians and your purse

Sustainability is a core topic for most engineering businesses and meeting market needs and treading carefully on the planet is not always an easy mix, especially with the current backdrop of supply chain issues and high energy prices. Achieving ecological balance in engineering workshops is about challenging the status quo. One area that lends itself perfectly to upending long-held conventions is the cleaning of parts and components. Using oil and grease daily has an obvious environmental and health and safety impact, therefore the industry welcomes with open arms the bioremediating parts cleaning solutions that improve any environmental impact and comply with H&S and ISO14001 regulations.

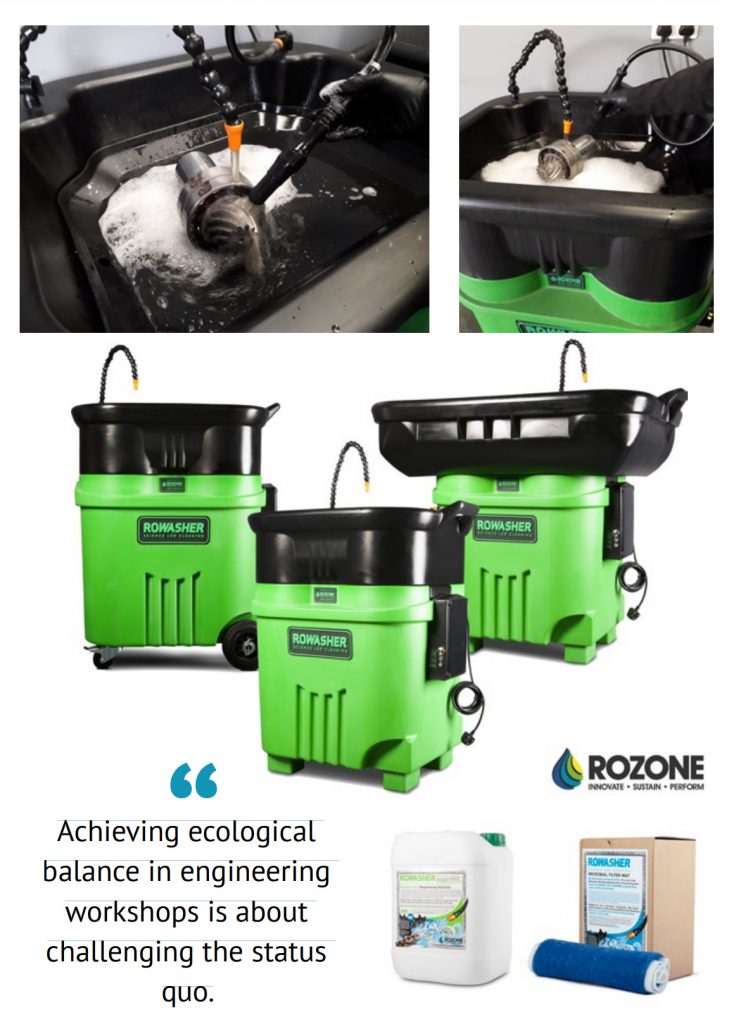

Rozone’s ROwasher is a parts washer that uses the science of Bioremediation to convert toxic oil and grease products (hydrocarbons) into non-toxic, harmless natural gases and water. This is achieved with minimum waste or environmental impact, whilst retaining excellent cleaning credentials. Learn more about the ROwashers features and benefits here.

The pH neutral cleaning process is water-based, using the triad of the ROwasher machine, the ROwash degreaser and microbial filter mat, to achieve what the solvent ‘sink on a drum’ would accomplish. Except no solvents such as methylated spirits, kerosene or diesel are involved. No waste removal is required nor any regular service contract.

Bioremediating parts washers have been around for decades but the ROwasher is the first UK designed and manufactured machine and is the first sign of innovation on the market in all that time. Find out more about the ROwasher and consumables here. If you would like to learn more about bioremediation and nature cleaning nature, have a look here.

Lowest cost parts cleaning The cost benefits of the new ROwasher have been put through rigorous tests in controlled laboratory trials and we know that the running costs are the lowest compared to all other parts washers on the market, using 54.5% less energy than our previous machine. The consumable costs of a ROwasher are the lowest on the market. The ROwasher uses the least amount of fluid of all other competitor parts washers and 43% less fluid than Rozone’s previous standard parts washer and 33% less than the previous mobile option.

Why is bioremediation essential for workshop cleaning? Using a bioremediating parts washer means that the best clean becomes possible without any risk to technicians or endangering the planet. Using the ROwasher, oils and grease will not leave pollutants down sinks, on rags, in hazardous waste or washed-off solution.