Revolutionary technology allows metal parts to be stress relieved without using natural gas or electric furnaces.

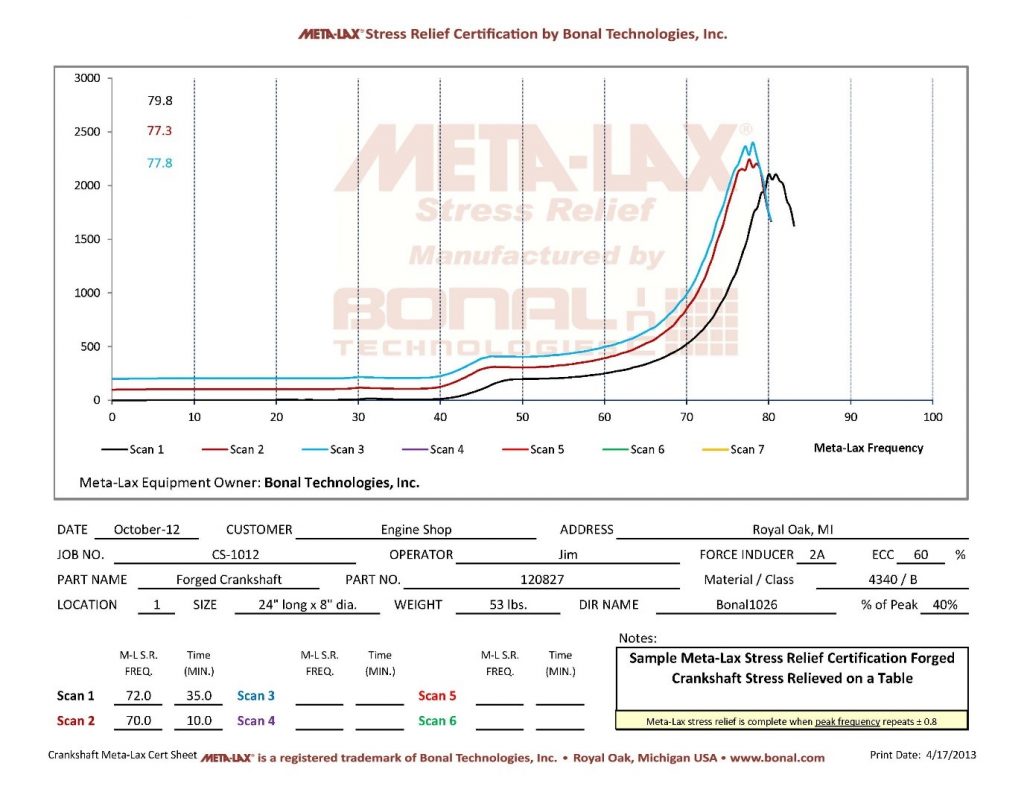

Bonal Technologies was awarded “Manufacturer of the Year” for 2022 for its revolutionary non-thermal stress relief process called Meta-Lax®. The patented Meta-Lax technology is revolutionary because it is the first vibration stress relief process that is as good as heat treat stress relief on a consistent basis. As a result, Meta-Lax stress relief is making a worldwide impact on the metalworking industry.

According to the US Department of Energy – “Meta-Lax is a proven substitute for 80 to 90% of the heat treatment stress relief applications.” The USDOE further stated in their IMPACTS magazine that Meta-Lax can reduce energy consumption for stress relief by up to 98% and the pollution that goes with it. Meta-Lax equipment only needs the energy equivalent of a coffee pot to operate.

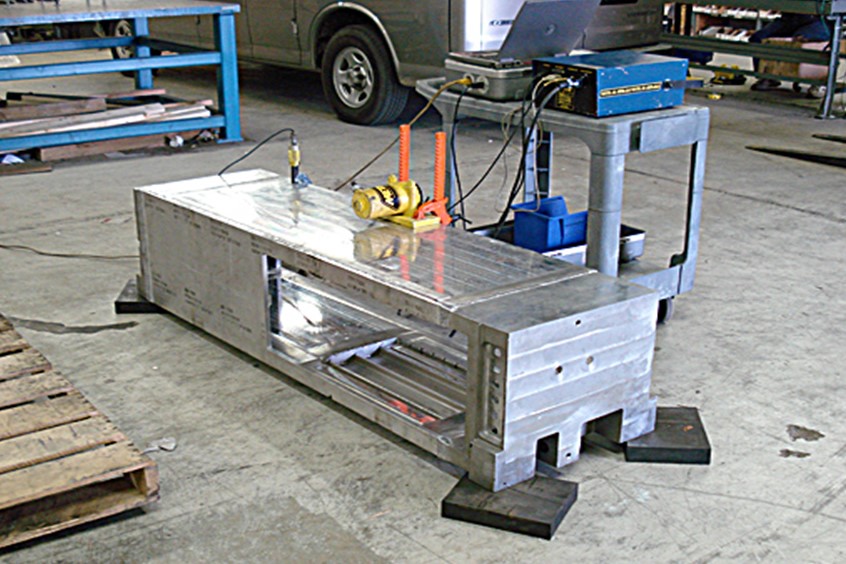

Meta-Lax stress relief processing is 8X faster than heat treat, costs a fraction of the costs associated with heat treat stress relief, doesn’t cause treatment distortion or change to the mechanical properties of the treated workpiece. Many customers, especially in the aerospace and defense industries, like the certification documents produced by Meta-Lax equipment as proof of completion. All companies appreciate the fact that Meta-Lax processing can be applied whenever and wherever needed without additional transportation.

Meta-Lax Technology can be applied in two ways – 1) as a stress relief process and 2) during welding

- Meta-Lax Technology – as a stress relief process

Most commonly, Meta-Lax is used in place of heat treat stress relief. But the capability of Meta-Lax goes way beyond the limits of heat treat stress relief. Here are 15 areas that are now possible to stress relieve metal parts without difficulty:

- Tubular steel and aluminum weldments

- While-You-Wait

- Improve quality

- On-site and outdoor

- Non-Ferrous metals

- Large workpieces

- Heavy workpieces

- Hardened metals

- Near net and semi-finished workpieces

- Assembled

- Differential thicknesses

- Multiple metals simultaneously

- Structural steel and aluminum weldments

- Stationary workpieces

- During welding to eliminate stress as it is being induced, thereby eliminating the need for post weld stress relief

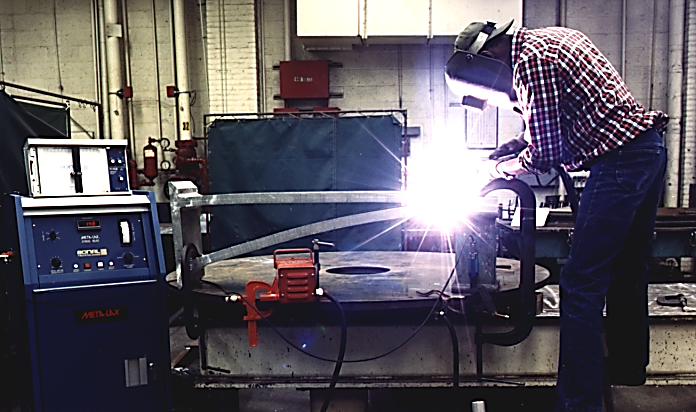

- Meta-Lax Technology – as applied during welding

Meta-Lax technology can be applied during welding to improve welding performance and product quality. When Meta-Lax is applied during welding, the mild vibrations enable the base metal to be more receptive to the molten metal. This is evidenced by easier welding and in reducing or preventing many weld related problems. Meta-Lax applied during welding can make an impact in 10 different areas:

- Prevent 50-90% distortion from welding

- Prevent 50-90% weld cracking – upon cooldown and in service

- Weld faster, up to 25% faster

- Reduce pre-heat temperature, up to 150OC (300OF)

- Reduce porosity, even in corners

- Easier to weld hard-to-weld metals – stainless steel and cast iron

- Easier to weld out of position – vertical and overhead

- Easier to weld dissimilar metals

- Reduce undercutting and blow-through

- Eliminate need for post-weld stress relief

Meta-Lax technology and equipment are available from Bonal Technologies.

Bonal Technologies, Inc.

(248) 582-0900 or 1-800-Meta-Lax

www.Bonal.com

info@Bonal.com

1300 N. Campbell Road

Royal Oak, MI 48067 USA