Croft Filters – Quality bespoke filtration solutions

Croft Filters are a leading UK manufacturer of over 34 year experience, specialising in the manufacture of high quality custom filters. The Company supplies a variety of diverse industrial sectors, including: Chemical, Food, Beverage, Oil and Gas, Pharmaceutical, Energy and Automotive amongst others. Notably, Croft’s products are widely used among engineering firms operating within different sectors.

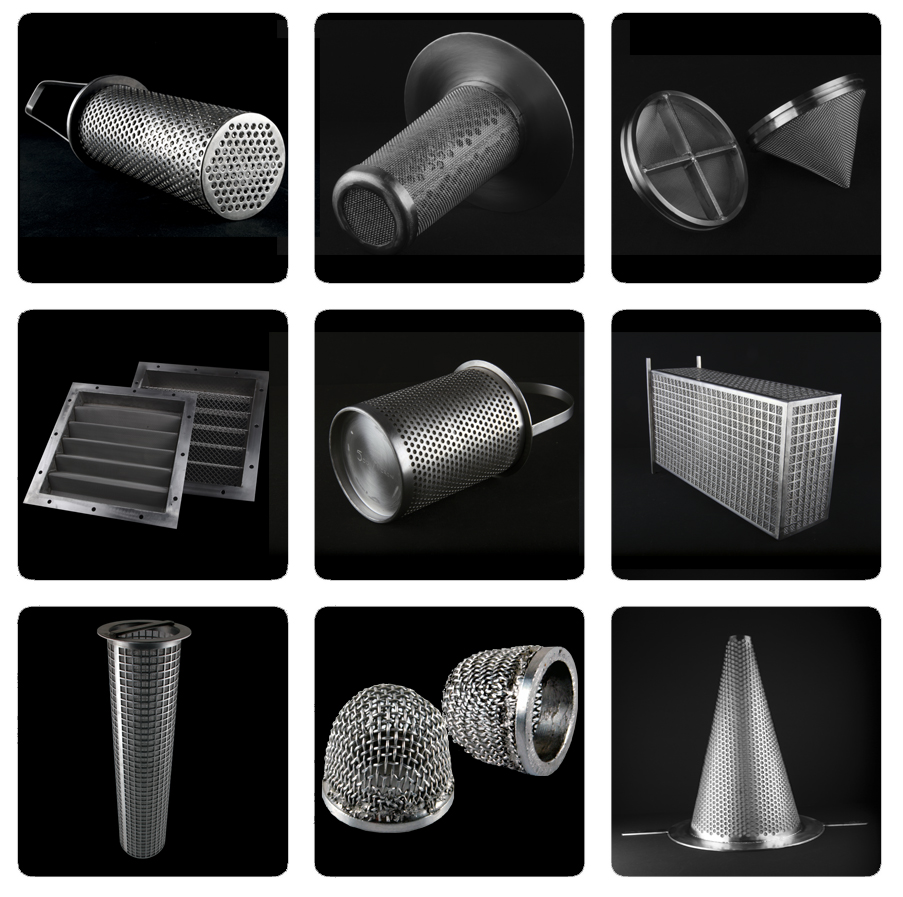

Witches’ hat filters

These filters are composed of a perforated cone supporting one or more fine wire meshes which maximise the flow area, effectively reducing resistance and ensuring reliable operation. The well-established, simple yet effective design makes them very popular for all kinds of industrial applications. As witches’ hat specialists, Croft Filters can manufacture them rapidly from basic sketches to final products with a pore size as small as 1 micron to suit each customer’s requirements.

Filter elements

Croft Filters can provide filter elements to customers’ own design or offer an alternative solution to suit specific requirements. Filter elements can be manufactured from combinations of perforated plate, wire mesh and knitted wire mesh in a variety of different materials. These elements can be designed to fit existing filter housing.

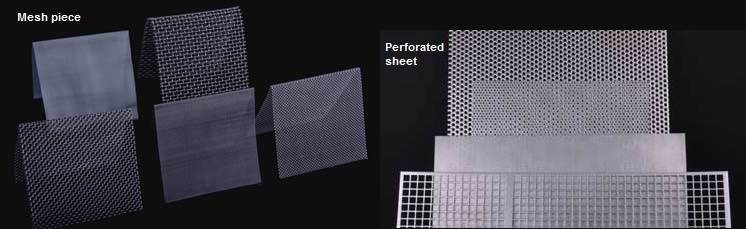

Quality perforated and mesh materials and components

Croft also supply stock and custom perforated sheet and mesh piece used in various engineering applications, they can be produced quickly and to precise specifications. Perforated tubes, mesh tubes and mesh discs are highly requested components among Croft’s clients. Croft can punch various materials such as Aluminium, Mild Steel, Stainless steel amongst many up to 6mm thick and to large panel sizes; form and shape those panels with curves & bends where possible to deliver the exact products each customer needs.

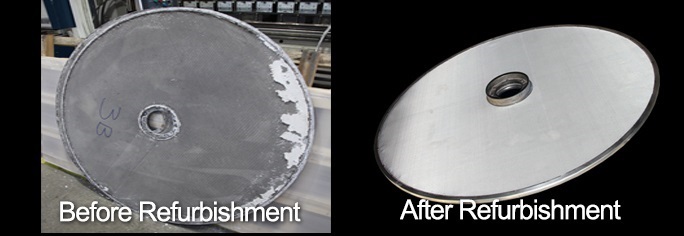

Services: Cleaning, repairing and refurbishing

Croft can repair customers’ existing filters or replace damaged components to help them make the most out of their filtration frames. A particular customer operating within the Chemical industry has benefited from these services by having over 100 leaf filters cleaned and refurbished (See the case study here).

Additive manufacturing

Croft also specialise in the Additive Manufacture (3D Printing) of complex metal components. Benefits of the Additive process, such as: Part weight reduction, Multi-part to single component and Expanded design capabilities, allow the customers to re-think their approach to their designs in order to improve the efficiency, utility or aesthetics of their parts.

Other custom filters

Croft Filters based in Warrington, England can manufacture filtration solutions in any shape or design, including basket strainers, duplex filters, vacuum filters, cylinder filters, screen filters, last chance filters, inline filters, pleated filters and slot tubes in perforated plate, wedge wire and woven wire mesh.

Quality of both product and service has been the key to Croft’s success; the Company takes great pride in understanding their customer’s needs, quickly supplying them with a high-quality product that exceeds customer’s expectations.

For more information about Croft’s quality custom filters:

Call 01925 766265 or Email sales@filters.co.uk

Contact Information:

Phone: 01925 766265

Email: sales@filters.co.uk

Website: www.filters.co.uk