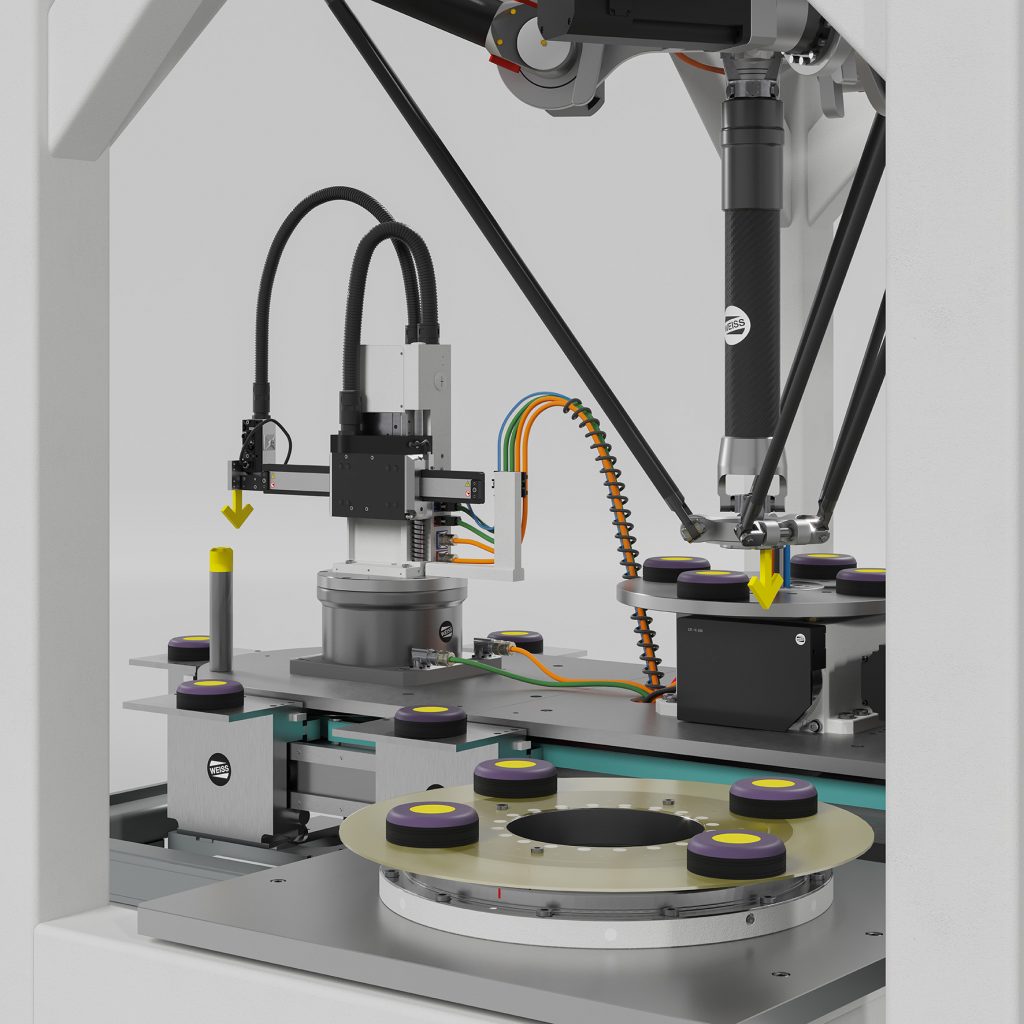

Easy integration of WEISS components and subsystems

When automation components can be combined with each other, this reduces the engineering effort, significantly shortens project runtimes, and the start of production can take place sooner. Not only can WEISS products be combined, they can also be easily integrated in the overall system as functional subsystems.

Fully functional subsystems using WEISS Linear Transfer Systems as a platform enable

system integrators to speed up the project planning stage. Integrating them into the

higher-level system and completing them with additional actuators is quick and easy.

(WEISS-Subsystem-LS

There are quite a few aspects to keep in mind when automating assembly processes. The efficient implementation of each step must be defined, and the right components must be combined to make a fully functioning system. To achieve this, WEISS offers an extensive portfolio of automation components, assemblies, and subsystems. Because WEISS solutions can be combined and integrated, equipment engineers and system integrators can focus better on the actual processes, quality, and interface issues. The selection of components is no longer a limiting factor.

Linear transfer systems as the basis

Linear transfer systems from the LS series are used as the basis for such subsystems. They are designed to achieve linear, continuous assembly processes in a tight space. At the same time, the LS linear transfer systems are the perfect platform for other WEISS components such as HP Pick & Place modules, Delta Robots, Rotary Indexing Tables, or Linear Axes. WEISS works in close coordination with system integrators, machine builders and users when engineering these functional subsystem solutions. Because use cases differ from one customer to the next and from one end product to the next, a major part of the gained efficiency lies in the design of the Linear Transfer Systems as a platform and the appropriate combinations of the relevant standard components. WEISS solutions are mechanically matched to one another from the start. At the software level, the W.A.S. Control Packages ensure that components can communicate with each other and be integrated at any time. The packages are compatible with one another and, because of different interfaces, with the higher-level PLC too.

Simulation models as decision-making tools

More and more often, digital tools and simulation models for virtual commissioning provide the needed support when selecting the right components. Starting as early as the planning phase of the assembly line, each individual product and subsystem can be compared with one another and optimized. This prevents potential errors, efficiency losses and overengineering, which also saves time and money and gives system integrators and end customers decisive benefits. Digital product add-ons offer added value even before the start of production.

Fully functional subsystems using WEISS Linear Transfer Systems as a platform enable

system integrators to speed up the project planning stage. Integrating them into the

higher-level system and completing them with additional actuators is quick and easy.

(WEISS-Subsystem-LS

Full application scenarios at a glance One advantage for system integrators and end customers is the holistic view that WEISS enables. If high forces are needed for press-fit or screwing processes, they must be implemented by the handling system and tolerated by the underlying platform. The combination of the Gantry and the LS Hybrid meets these requirements. Gantries from WEISS bring themselves into position with high precision and reliability. The workpiece carriers from the LS Hybrid series accommodate very high process forces of up to 1000 N without support. Due to the straightforward synchronization of the WEISS DR Delta Robots with the LS series, conveyor tracking is an easy process to handle. The Delta robot simply performs its task, while the conveyor section of the LS Hybrid continues to run without interruption. The response times are roughly two milliseconds, so the response to changes is virtually instantaneous.

In the electrical industry, life sciences, medical technology, or consumer goods the work often involves assembling small parts. As a result, the assembly line should have the smallest possible footprint. This is another area where the Linear Transfer System variants from WEISS are impressive, as they are designed to be extremely compact from the very start. The HP Pick & Place modules are an ideal add-on for handling small parts. The HP 70 module is only 60 millimeters wide. Its compact design means that multiple operations can be carried out in parallel at a single processing station, which significantly increases the output.

A well-balanced line concept requires reliable automation components that can be combined. The WEISS portfolio offers machine builders and system integrators compatible components that are easy to integrate. Reliable, high-performance overall solutions are developed in partnership with WEISS experts