LUBCON Lubricants UK Ltd. – Maximum efficiency by streamlining lubrication tasks

The technical requirements for maintenance and the breadth of the tasks to be completed are more demanding than ever. Many maintenance engineers now spend more time on documentation and administrative tasks than on the actual maintenance of production machinery.

Due to lack of time, planned maintenance is repeatedly postponed or sometimes avoided completely. Tasks such as regular lubrication and condition monitoring – for example, oil analyses, filter testing, visual inspections – and the functional testing of automatic lubrication systems are very often discarded due to lack of time and supposedly low priority or are only carried out with insufficient care. This, in turn, leads to serious machine failures due to inadequate lubrication. The effort required to eliminate the problem and the associated loss of production often exceeds the time and costs of previously omitted lubrication tasks immensely.

If warranty claims are subsequently made to the system manufacturer, the operator of the system is obliged to prove that all lubrication tasks were carried out in accordance with the information in the operating instructions. The documentation and the actual condition must correspond accordingly. For example, if a damage analysis is carried out on a failed bearing and lubricant, the expert can often quickly identify whether it is a lubrication-related failure (e.g. lack of lubricant). If this is the case, warranty claims are often rejected.

Lubrication survey for improved task management

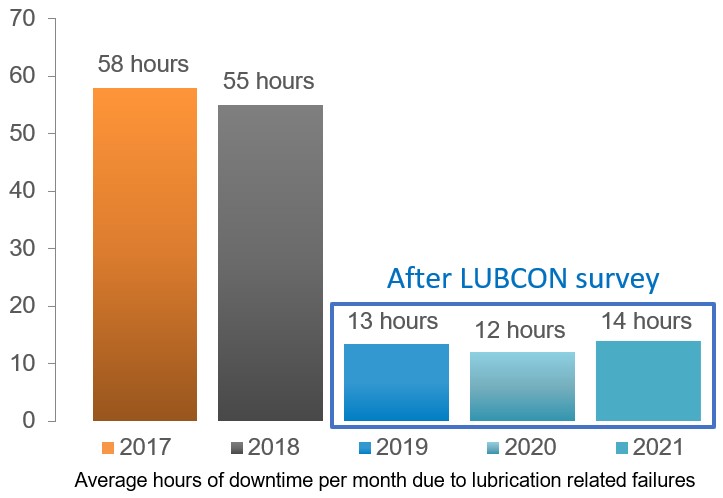

The main goals of modern production are the same regardless of the industry: high asset availability and efficiency. Regarding machinery lubrication, this means that a high proportion of lubrication-related failures must be avoided at all costs. To support these goals, LUBCON has developed a sophisticated survey procedure and a lube management program called ‘Smart Task Control’. This application software works with modern NFC technology (Near Field Communication) and supports maintenance staff in carrying out and documenting lubrication and maintenance tasks.

The requirement for the introduction and successful use of Smart Task Control is a thorough preparation. What is important, is not only a clear idea of the company’s goals, but also good knowledge and analysis of the current situation. LUBCON’s experienced engineers work together with management and maintenance to determine the required data and machine parameters, which serve as the basis for creating a digital lubrication plan. The process of the survey involves rationalising the number of lubricants used on site as well as an optimisation of methods, consumption and intervals, without compromising lubrication efficiency. This streamlining process leads to a reduced stock inventory and therefore contributes to cost savings. Ensuring that the right lubricants and quantities are applied will protect machinery, prolong component life and reduce waste.

Advantages of a LUBCON lubrication survey on site:

- Reduced downtimes

- Reduced stock inventory

- Lower risk of cross-contamination

- Reduced overall consumption

- Simplified lubrication plan

- Clear labelling of lube points to match with lubricants/lubrication equipment

- High potential to save time and costs

- Improved safety

- Reduced waste

Example of possible achievements

All tasks with one click

The optional usage of LUBCON’s Smart Task Control software provides users with a tool to carry out tasks quickly and accurately which contributes to reducing machine downtimes, costs and time expenditure.

After logging in on a tablet or computer, the maintenance engineer receives an overview of the upcoming tasks, the resources required such as lubricant type or tools and optional route planning. After scanning the NFC tag on the machine to be serviced, the engineer will receive a detailed task list that provides precise information about what needs to be done and where. This listing may include the following information:

- Asset identification

- Safety instructions

- List of all lubrication or maintenance points

- Pictures of the individual points

- Lubrication point designation, optional with colour code

- Task description, e.g., relubrication, checking of fill levels, changing filters, etc.

- Lubricant type

- Amount of lubricant

- Lubrication interval

- Other comments

This detailed task description in conjunction with a clearly marked lubrication point using labelling and colour coding ensures that the right lubricant is used at the right time, in the required amount, even with frequently changing maintenance personnel.

Digital documentation

After the tasks have been processed, this is acknowledged by the operator and the system status is updated after the NFC tag is scanned again. This status can be accessed at any time by maintenance management via the dashboard integrated into the program. The digital data available at hand provides comprehensive information and options:

- Clear overview of open and completed maintenance tasks

- Simple and flexible task planning

- Digital documentation (also as proof of guarantee)

- Assignment of tasks and responsibilities

- Lubricant consumption and inventory

- Detecting weak points, identifying optimisation opportunities

- KPI integration

LUBCON’s lubrication survey and the subsequent optimisation process, together with Smart Task Control will boost the efficiency of your maintenance when carrying out lubrication tasks. It will ensure that the correct lubricant is used at the right time, in a sufficient amount by using the most appropriate method.

Contact details:

LUBCON Lubricants UK Ltd.

Phone: 01323561030

sales@lubcon.co.uk

www.lubcon.co.uk