New Gas Addition Module for Continuous Flow Reactors

The Gas Addition Module from Uniqsis provides a safe and efficient means of performing gas-liquid reactions undercontinuous flow-through conditions. Its primary purpose is to provide a solvent feed stream pre-saturated with gas, but it can also be used as a reactor in its own right.

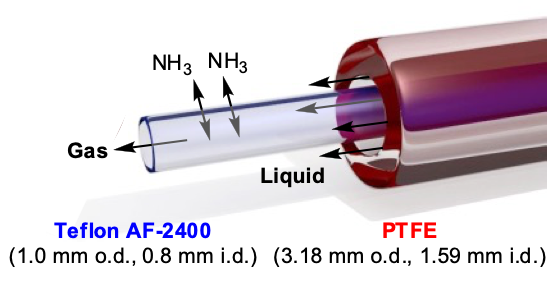

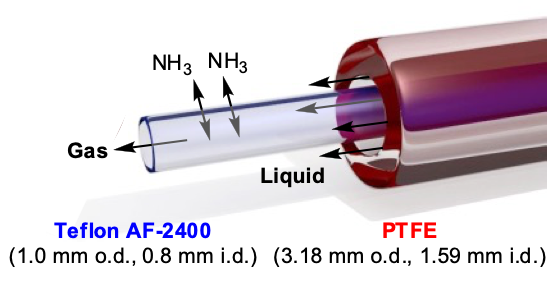

Fast, controllable gas saturation: The ingenious ‘tube-in-tube’ design promotes rapid diffusion of pressurised gas through gas-permeable tubing to quickly generate a continuous gas saturated solvent stream in typically less than 10 seconds (for H2). No undissolved gas bubbles to disrupt control of pressure and residence time!

Wide variety of applications at your fingertips: Compatible with a wide range of reactive gases (e.g. CO, CO2, H2, D2, ethene, ethyne, SO2) and organic solvents (e.g. THF, MeCN, MeOH, PrOH). Effortlessly perform heterogeneous and homogeneous gas-liquid reactions such as hydrogenation, ozonolysis, carbonylation, and direct synthesis of carboxylic acids.

Flexible: Connect in-line with any FlowSyn or other continuous flow reactor system.

Gas Manifold (Optional; UQ1095M): An optional Gas Manifold is available for use with the GAM II if required. This is made of stainless steel and comprises an inlet with gas burst relief valve and an outlet with a pressure gauge and needle valve. The seals in the valve are made of Viton as standard.

Safe: Integral safety features (protective glass cover and gas pressure release valve) and the use of small gas volumes ensure safe operation in the lab. In addition, the convenient optional Portable Gas Reservoir (UQ1098) avoids the need to bring bulky pressurised gas cylinders into the lab

Steve Evans

Chief Commercial Officer

Uniqsis Ltd

29, Station Road

Shepreth

Cambs.

SG8 6GB

UK

Ph: +44 (0)845 864 7747

Email: info@uniqsis.com

Web: www.uniqsis.com