Scaled Ltd

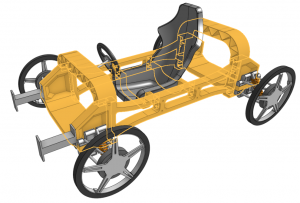

Scaled Ltd have developed an in-house 3D printing system based on robotics. Over the course of a weekend in August, Scaled printed an entire concept vehicle chassis to demonstrate how 3D printing could be used for vehicle applications. 3D printing in thermoplastic composite materials is now a viable manufacturing technique for structural applications, fast-make tooling for composite prototype and large-scale jigs. And the cost point for low volume automotive production is now well within reach.

The chassis build has far-reaching implications. Today, the world is facing competing pressures: high rates of consumption of fossil fuels is affecting the climate and levels of pollution; At the same time, standards of living are going up across the globe. More and more people are earning enough to demand the benefits of powered transportation. One solution to these competing pressures is electric vehicles. But electric vehicles have failed to answer a fundamental question: is it necessary to use a 4-tonne van to transport a payload of 150 kg?

The best solution is a vehicle only as heavy as is needed for its task. A last-mile delivery vehicle that weighs 150kg saves significant energy when compared with a 4-tonne alternative (however it is powered).

To produce vehicles that exactly meet the needs of their task you need a flexible manufacturing technology such as Scaled’s robotic 3D printing system. A famous Henry Ford quote is “Any customer can have a car painted any colour that he wants so long as it is black”. But with Scaled’s 3D printing the ambition is quite different: “Any customer can have a vehicle of any design that they desire.”

Robot arms used in car plants are automated for one repeatable task. For Scaled, the robot is programmed for different pathways over and over again automatically, producing new 3D printed parts each day.

This is production using a completely flexible production system, in theory able to produce hundreds of variants of vehicle from the same small digital factory, with variants’ design changes unconstrained by tools, jigs or core manufacturing processes.

Watch out for more developments and a rolling vehicle.