Rapidly Develop Process Control and User Interfaces with PanelPilotACE

Lascar’s PanelPilotACE is a unique industrial control display platform ideal for the rapid development of touchscreen automation and user interfaces – without writing code. There’s no need to start from scratch, instead develop your application using Lascar’s free Design Studio software which provides powerful, easy to use drag and drop tools to build the complex functionality you need. Forget months of programming and hardware headaches, get a development edge with PanelPilotACE and deliver your project on time!

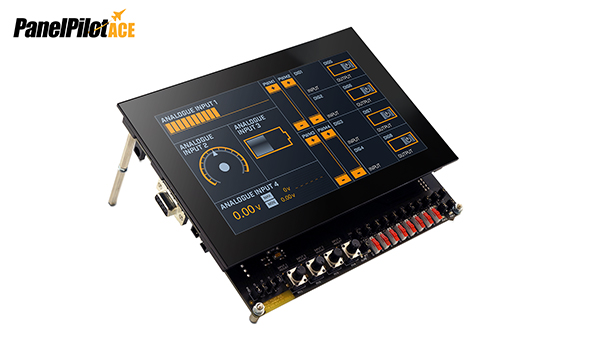

PanelPilotACE has two display sizes, the 4.3” (SGD 43-A) and 7” (SGD 70-A). These feature high-resolution capacitive touch screens, four 16-bit bi-polar analogue inputs, eight digital input/output pins, two alarm outputs, four PWM outputs, RS232 comms, RS485 and Modbus comms (requires add-on board for SGD 43-A), CAN bus (SGD 70-A only, requires add-on board) and FTP transfer of logged data via wired Ethernet (SGD 70-A only), making them extremely capable units. Both are very competitively priced, with discounts available on volume purchases.

Free to download for you to evaluate, the PanelPilot Design Studio software offers a wealth of functionality for building multi-page, intelligent display interfaces, allowing you to add background images, text elements, analogue and digital style meters, touch screen navigation, complex logic statements, serial communications, data logging, trend graphs and maths functionality. The Design Studio ‘Maths Builder’ is a powerful tool for performing calculations on values held within your project. A full range of mathematical operators are available to users: from simple addition and multiplication, through to exponential and trigonometric functions. These functions can be applied to most properties and variables within an application, such as calculating power from two analogue inputs, or adjusting the value of a variable based on a touch screen input.

The software includes an emulator, so you can design and test your interface for free before buying any hardware. PanelPilotACE development kits that include a development board for testing all the input/output functionality along with the display are also available. You’ll find further development resources online at the PanelPilotACE University https://www.lascarelectronics.com/panelpilotace-university/ which provides video tutorials and shares templates and graphics for you to use in your display project. Alternatively, we offer a “one-stop” Custom Design service where our experts can build your display project for you.

PanelPilotACE offers data logging capabilities, supporting high-resolution analogue and digital logging together with fully customisable on-screen graphing. This means the Design Studio software can be used to create applications that not only display data, but also record, store and analyse it on the device itself. You can monitor up to four 16-bit analogue inputs at any time with each data set holding well over 1 million individual readings. Sample rates from 5 seconds up are supported. The channels can be used concurrently so users can design logging functions to meet their exact requirements. A free Windows application is available to download logged information to a PC using the USB port on the device for further analysis if required.

The PanelPilotACE Design Studio software is continually improved, with recent additions including:

PID Control

PID control functionality allows PanelPilotACE displays to be used as PID control units. Set P, I and D coefficients, then measure a process variable and use PanelPilotACE to correct to your desired set point, e.g. vary a fan speed to maintain a temperature.

Multi-Channel Data Logging

You’re no longer restricted to just one data logging channel – now you have 10. PanelPilotACE allows you to log any input to the device that can be defined numerically. Now record more temperatures at once, as well as other parameters including voltage and current.

Trend Graphs

The Trend Graphs functionality has been developed to display the new multi-channel logging feature, enhancing PanelPilotACE’s capability as a monitoring device. If you use an alarm threshold as one of your data channels, Trend Graphs will let you monitor logged data against alarm level.

Ethernet FTP for Logged Data

No need to connect your PanelPilotACE SGD 70-A to your computer via USB to obtain logged data – you can now use its Ethernet port to connect it to an FTP server. This Ethernet FTP capability allows quicker and more convenient data collection, particularly useful when you are running time-sensitive applications.

CAN bus

The S70-CAN add-on board provides a 3-wire CAN bus interface for the SGD 70-A, 7” PanelPilotACE. This means PanelPilotACE display technology can now be used in conjunction with the popular CAN bus protocol, opening up a wide-range of control and monitoring possibilities, including automotive applications.

Should you have any queries about PanelPilotACE, our sales support team will be happy to help on the number below.

For further information on PanelPilotACE displays, visit https://www.panelpilot.online/ACE

Download the PanelPilotACE Design Studio Software for free to try before you buy from https://www.lascarelectronics.com/software/panelpilot-software/panelpilotace-design-studio/

Lascar Electronics

01794 884567

https://www.lascarelectronics.com/