Free-to-attend training opportunity – June 26, Manchester.

Presented by PROFIBUS and PROFINET International and hosted by Endress+Hauser, this event addresses the key practical issues arising from the use of digital communications technologies in automated manufacturing and process industry applications, with particular attention to Industry 4.0 and the Industrial Internet of Things (IIoT).

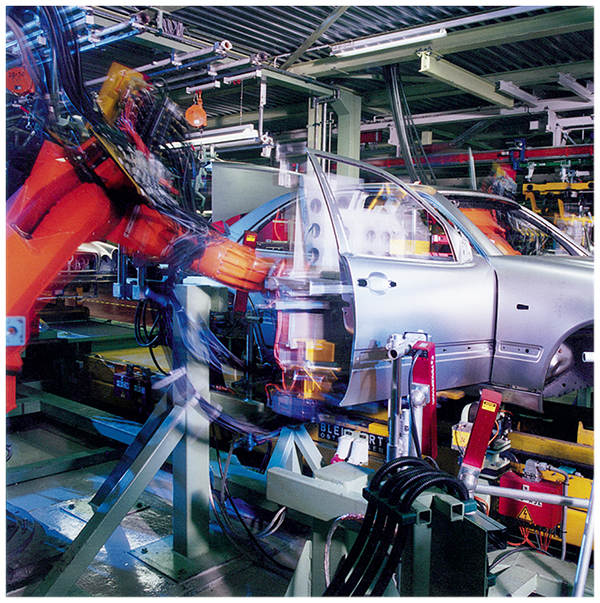

Covering key application areas such as control systems and energy management, pulp & paper, chemical, utilities, pharmaceutical, mechanical handling and logistics, robotics, automotive engineering, electrical and electronics assembly, packaging and printing, it focuses on the practical aspects of using PROFINET, PROFIBUS and IO-Link, from system design and safety considerations through to fault-finding and maintenance.

Draft Agenda

| Time | Item | Presenter |

| 09:15 – 09:30 | Welcome and introduction to exhibitors | Andy Smith, E+H |

| 09:30 – 10:00 | PROFIBUS International and basics of PROFIBUS & PROFINET | Mark Freeman, Siemens |

| 10:00 – 10:30 | PROFIBUS network design for Process Industries | Andy Smith, E+H |

| 10:30 – 11:00 | PROFINET network design | Andy Williams, Siemens |

| 11:00 – 11:30 | Coffee and exhibition | |

| 11:30 – 12:00 | Industrial network commissioning and testing | Dave Tomlin, Hitex and Xing Ye, Ideal Networks |

| 12:00 – 12:30 | PROFIBUS and PROFINET device configuration tools. | Phil Waterworth, Endress + Hauser |

| 12:30 – 13:00 | IO-Link for the “last metres” communication | Derek Lane, WAGO |

| 13:00 – 14:00 | Lunch and Exhibition | |

| 14:00 – 14:30 | Industrial networks safety & security | Peter Brown, CSA Group |

| 14:30 – 15:00 | Update on Industry 4.0, IIoT, TSN and APL | Derek Lane, WAGO |

| 15:00 – 15:15 | Summary, questions & close | Andy Smith, E+H |

Live demonstrations

Supported by an exhibition with demonstrations of actual tools used in configuration and maintenance, the seminar will be of great value to Designers, Production/System Engineers, Instrument Technicians/Engineers and C&I Engineers involved in the design, operation and maintenance of modern automated factories and process plant.

With nearly 80 million nodes installed worldwide, PROFINET, PROFIBUS and IO-Link are truly market leaders, providing state of the art digital communications addressing all the needs of manufacturing and process industries, significantly lowering capital expenditure on installation, commissioning and maintenance. They offer unprecedented integration of automation, control, monitoring and safety systems using standardised and widely supported communications and networking solutions.

This seminar is ably presented by specialists from PI UK member companies. Attendance is free of charge to pre-registered delegates from the User community, i.e. companies that own, operate, design, build or maintain automated process plant and manufacturing facilities. The event will provide delegates with an excellent networking opportunity and the ability to speak to experts.

More information and online Registration

In case of difficulty contact Ann on tel: 00 44 207 193 8018 or email admin@profibus.org.uk

Abstracts

PROFIBUS International and basics of PROFIBUS and PROFINET

Mark Freeman, Siemens

An overview of the Group’s structure and global representation, taking a look at the protocol basics and their differences, plus showing the progress of the number of installed devices from the group’s supported technologies and relating these figures to their market share.

PROFIBUS Network Design for Process Industries

Andy Smith – Associate Director of Engineered Solutions – Endress+Hauser Ltd

The successful application of industrial networks depends on good planning and robust design. We’ll look at some of the considerations around PROFIBUS DP/PA network design, networking components, network drawings and the tools available to assist you. As ethernet based networks become more popular, can the existing plant networks continue to be utilised?

PROFINET Network Design

Andy Williams, Siemens

It is widely accepted that the most important decisions are made at design stage of a project. This presentation examines the fundamental principles of good network design for PROFINET systems, although many of the ideas are applicable to PROFIBUS and other networking systems. The presentation will discuss the main factors that must be considered at the design stage of an automation system. Practical examples will show how facilities for health checking, fault-finding and maintenance can have a crucial impact on plant availability. The presentation will also examine how properly thought out network monitoring and redundancy can drastically affect plant up-time and thus profitability.

Industrial network commissioning & testing

Dave Tomlin, Hitex and Xing Ye, Ideal Networks

Take a walk through the process of certifying a new PROFINET (or any other industrial Ethernet) against the standards and see how easy it can be, then look at a few gotchas that can easily be avoided by careful planning.

PROFIBUS and PROFINET device configuration tools.

Phil Waterworth – Project Engineer – Endress+Hauser Ltd

A look at the available device configuration tools and their development including the move to unify the different types into one format – FDI. This will be followed by a live demonstration of PROFIBUS and PROFINET device configuration using an existing open platform and web browser option.

IO-Link for the “last metres” communication

Derek Lane – Process Automation Manager – WAGO Ltd (Deputy Chairman – PI-UK)

An overview of IO-Link. The digital point to point solution for sensor actuators and more, typically using standard 3-wire M12 cables extending fieldbuses such as PROFIBUS and PROFINET for the last 20 meters.

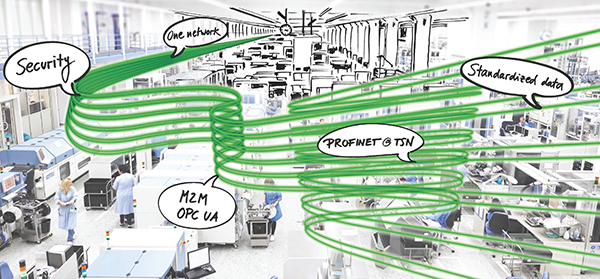

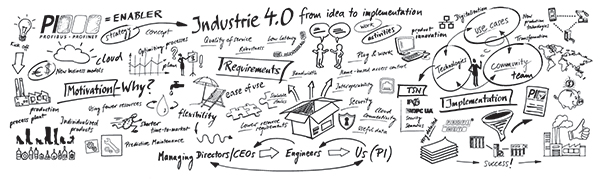

Industry 4.0 and the Industrial Internet of Things (IIoT)

Derek Lane – Process Automation Manager – WAGO Ltd (Deputy Chairman – PI-UK)

A short journey to explain IIoT The Industrial Internet of things, IND4.0 from IND1.0 and Big Data. How PROFINET is placed as the ideal Industrial Fieldbus to fulfil the above, how its implemented and why you should consider it. Some of the myths explained.

More information and online Registration

In case of difficulty contact Ann on tel: 00 44 207 193 8018 or email admin@profibus.org.uk

dav